Motion Control Platforms, White Paper

White Paper

How to Determine if a Homegrown Controller or an Established Platform Is the Best Choice for Your Machine

Matt Davis

3D Metrology Applications & Support Engineer

The time has come once again for new product design. Your ultimate goal is to enter the market with a new machine in a timely manner. Most importantly, you need something that is reliable. You have completed your research on performance and specifications, and you know which new advancements need to be integrated into your machine to meet your market’s needs. Your value is knowing how to leverage your expertise into this new tool to make it a cutting-edge solution. Lastly, you have a target price of what the market will pay for this new machine.

But, questions still remain. Do you need to start from scratch on this new build or are you able to upgrade the current machine in a significant manner to differentiate it from what currently exists? Can you reuse parts of the previous generation machine like the frame and the electrical cabinets? Do you need to make room for a higher level of automation by adding programmable logic controllers (PLCs) and additional input/output (I/O) devices?

Are the controls you were using previously sufficient for controlling this newer, faster, more accurate machine? Although open-loop stepper motors have been sufficient in the past, do you now need to look into closed-loop control? Do encoder resolutions need to be increased to accommodate the higher precision needed in this machine? Is there in-house expertise to design and create new controls for this machine in a timely manner? Would the use of an off-the-shelf controller allow your competition to copy you? Can you customize an off-the-shelf controller to differentiate your machine from the competition?

These are certainly not easy questions to answer, and the answers will invariably change from machine to machine. Since the control architecture is a critical element of the new machine, choosing the wrong platform can doom your project to failure or require workarounds that add cost and negatively impact performance. Typically, once these workarounds are created, they remain. The fear in changing is that some other unknown issues will arise and require similar workarounds in a different section. This fear allows a subpar solution to be used on newer builds and can even hamstring further enhancements to the machine.

New developments allow you to reevaluate past decisions and improve them. The switching costs are not always as high as assumed, and the benefits can be realized early in the project.

However, having the capability to do something isn’t the same as having the resources needed to accomplish it. Building on a solid foundation will allow your engineers to do what they do best – adding value to your system – instead of reinventing the wheel.

In-House vs. Outsourced

A variety of microcontroller and chipset development kits that allow developers to design and build a control architecture from scratch are readily available. Dedicated motion control companies build off of similar chipsets to give the end user a pre-built development environment and underlying control architecture to program the machine without worrying about the underlying framework. This distinction is pronounced in terms of development time.

Building in-house does give you full control over everything. It creates a blank canvas that allows you to develop whatever you would like. This freedom comes at the price of a longer development cycle. More time will be spent on developing the framework and schema that will serve as the foundation for your process. All features, from bus compatibility to control signals, will need to be created. Open-source libraries can be used to speed up some of this development. Tying these packages together and ensuring everything works together will be a key aspect of this work. Licensing these different packages will also become a concern.

Using an off-the-shelf solution that you would need to work around because it cannot be modified to meet your needs or requirements is equally troubling and undesirable. Locking yourself into a rigid control scheme or a design that is difficult to adapt to your needs due to form or fit requires additional changes.

A better solution is one that allows you to build your own custom algorithms to run inside a robust controls environment. These custom algorithms that you create should be encrypted so that end users cannot reverse-engineer your routines. This allows for the best of both worlds: you can protect your intellectual property without having to worry about the integration of the mundane (yet complex) controls problems, like bus topology, amplifier integration and servo control.

Ease of Use

A control platform should enable and enhance innovation. An often overlooked aspect of a controller is its ease of use. Spending days to configure your axes and I/O just to get your basic process verified is time consuming, frustrating and costly. Ideally, after all wiring is completed, it should take no longer than a morning’s work to get all axes’ motion set up and tuned and all I/O points verified. If wiring issues arise, the controller should aid in diagnosing and fixing these problems, potentially even by rerouting signals via the control logic rather than rewiring. This leaves more build time for process-control testing and evaluation.

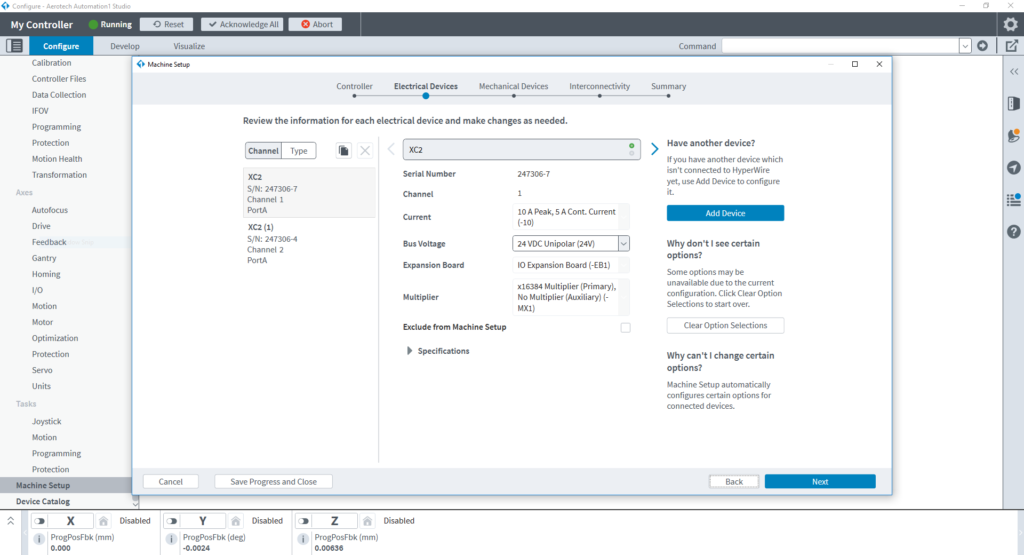

Given the myriad of parameters that are used for a given axis, having a configuration wizard to walk you through this setup is imperative. Without one, you will rely on one or two experts to set up everything. A controller that walks you through these settings enables a wider range of personnel to be able to handle these tasks without feeling overwhelmed. Figure 1 shows an example of a setup wizard in Aerotech’sAutomation1 controller platform.

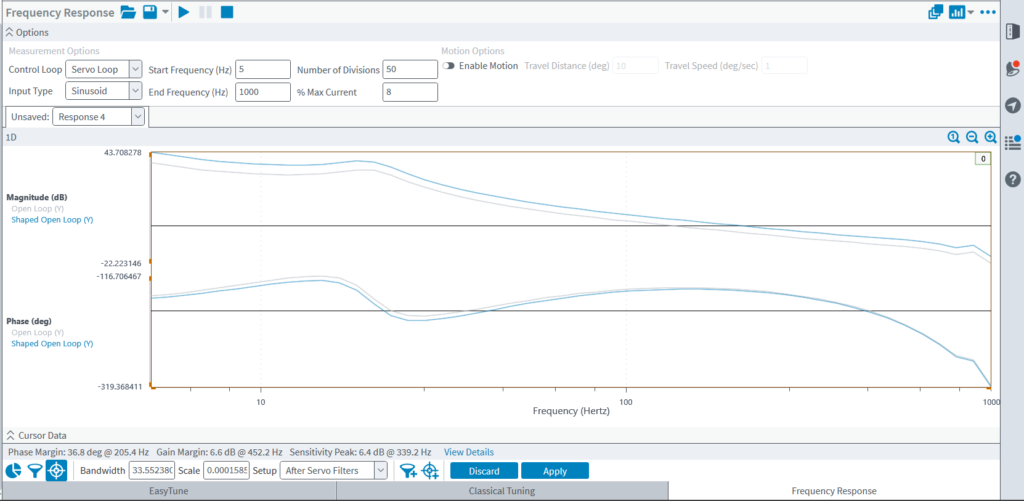

When servos are involved in a process, servo tuning is a cause for concern. The seemingly mystic art of servo tuning can cause hours of struggle, even for veteran engineers and technicians. A controller that can tune itself is the control engineer’s best friend. We all know that even the most sophisticated auto tune routines do not always work or achieve optimal performance. The controller that displays high-level control concepts for seasoned control engineers to manipulate allows for a deeper understanding of the level of performance that can actually be achieved. Figure 2 shows an example of a loop shaping tool used for graphic servo-loop tuning.

Once you have the servo-loop tuned and optimized, it is time to begin programming. Programming through this environment should be intuitive and flexible. The ability to write in more than one language or schema allows a variety of programmers to make the controller work for them. Using high-level languages like C,.NET and more to create the same program allows an even wider range of personnel to handle these tasks. The amount of time required to get up to speed on these features should take no more than a couple of days. Like anything, to become a master user requires repetition, but the system should be inherently easy to learn and intuitive. Ensuring your chosen controller has a toolbox that includes easy parameter generation and reliable autotuning utilities that actually work is a crucial first step. The tedium of initial setup and commissioning will be shortened greatly by a programming interface that can be used with multiple programming disciplines. All of these tools should live in an intuitive environment that has detailed help files and support resources geared toward optimizing your machine.

Solutions

At Aerotech, we have more than 40 years of experience developing motion controllers. We also have a reputation for producing motion solutions that are delivered ready to run. In configuring, tuning and programming these solutions for our customers, we have encountered many of the issues described in this white paper. To manage them, we have integrated features into our controllers like our bode plot tool that can show various response types to identify system resonances and margins, parameter setup wizards and even an EasyTune utility that sets gains and filters on a system. Our latest generation of controller,Automation1, combines a feature-rich modern programming language with an intuitive interface and powerful tuning utilities, giving you a platform to build on for years to come.