Webinar

Cylindrical Laser Processing of Medical Devices

About the Webinar

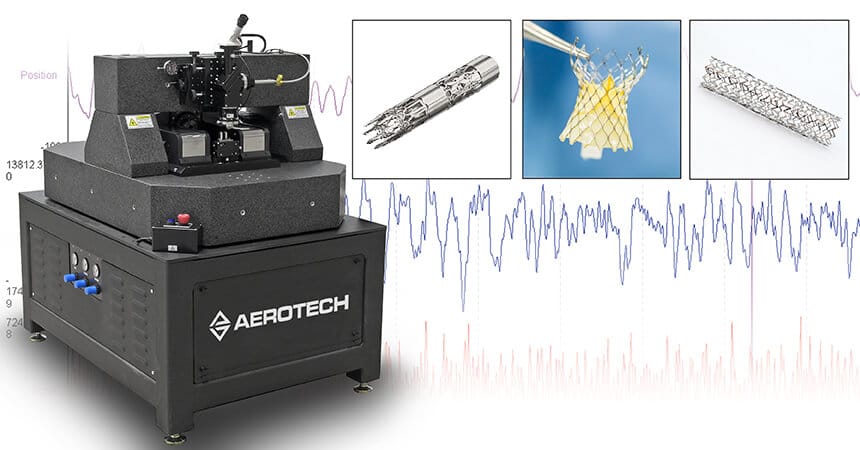

Laser processing has been used for decades to manufacture tubular medical devices, such as stents, valves, and vascular grafts. However, achieving the precision that is necessary for high-volume production is challenging. Driven by growth in minimally invasive surgeries and a desire to reach further into the body, devices continue to get smaller and/or more complex. Additionally, laser processing requirements are becoming more stringent to address laser-material interactions that are triggered by exotic new materials. Part accuracy and throughput requirements are higher than ever before to meet strict qualification standards and manufacturing efficiency goals. To overcome these challenges, tool providers, and even users, must have a good understanding of precision machine design fundamentals and modern motion control techniques.

Learning Objectives

Presenter Will Land, who has nearly a decade of experience solving challenging precision motion control and automation challenges for the medical device industry, will explain ways to improve your tubular laser processing systems.

Will will address:

- Machine design fundamentals that can drastically affect throughput and quality

- Control techniques that get the most out of a given machine

- Laser coordination techniques to uncouple material processing quality from motion optimization

Attendees will learn how to assess machine designs from different vendors and/or improve their own designs. They’ll learn which control features they could use on their own to get the most out of existing machines on the floor. Finally, attendees will learn how to augment their laser processing parameters to achieve consistent processing quality in various motion scenarios.

Who Should Attend

- Manufacturing and process development engineers employed by medical device companies who work with new product development groups to get new device designs onto the production floor

- Automation equipment engineers responsible for developing custom in-house tools for applications where off-the-shelf equipment isn’t adequate

- Anyone responsible for sourcing outside OEM equipment or who works with custom machine providers for device manufacturing

- Any person who is involved with designing or sourcing precision manufacturing machines, as the concepts apply to many other applications and machine types outside of medical device manufacturing

William S. Land II is a mechanical engineer and business development manager for Aerotech Inc., where he focuses on the medical device and laser processing industries. He has been with Aerotech for nearly a decade and has previously served in various mechanical engineering, applications engineering, and product management roles. He holds a bachelor’s degree in mechanical engineering from Penn State University, and a master’s degree in mechanical engineering from the University of North Carolina at Charlotte. He is currently pursuing an MBA at the University of Pittsburgh. You can contact Will at [email protected] or +1.412.967.6837.