ASR1100 Mechanisch gelagerter, direkt angetriebener Drehspanntisch

Unsere ASR1100-Serie ist eine Erweiterung des direkt angetriebenen Drehtisches ASR1000. Der ASR1100 verfügt zusätzlich über eine integrierte pneumatisch betätigte Spannzange, die eine sofortige Materialhandhabung ermöglicht.

>

Description

Specifications

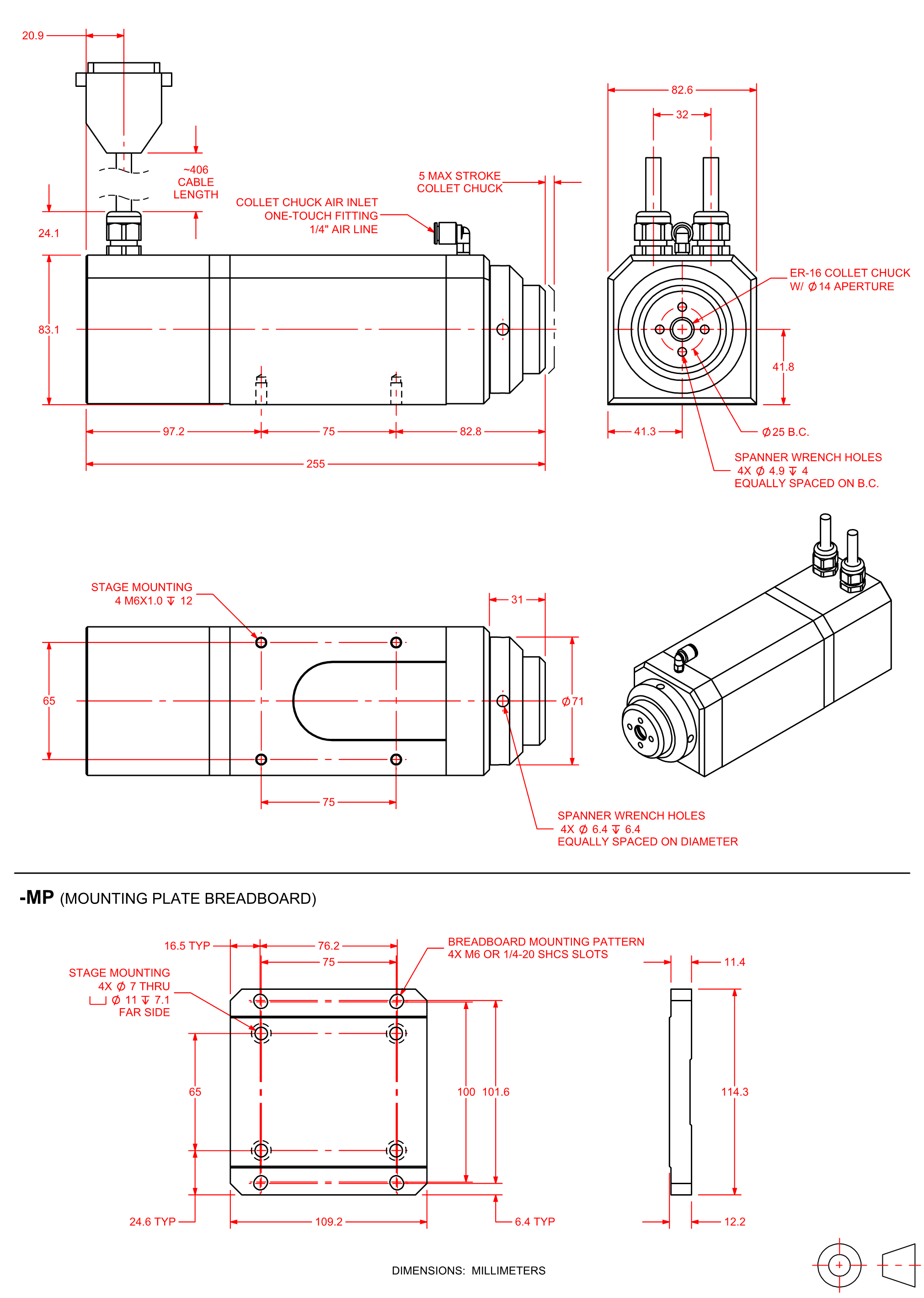

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Design Features

- Integral pneumatic collet chuck

- ER16 collet accepts 0.5 mm to 10 mm O.D. tubing

- Clear aperture for product feed-through

- Threaded collet retainer enables rapid tooling changeover

- Normally-closed collet configuration

- Low-inertia shaft for maximum acceleration

- Direct-drive brushless motor and encoder

- Maintenance-free, frictionless rotary union

- High-speed (2000 rpm) and standard-speed (800 rpm) options

Integral Collet Design

The collet chuck on the ASR1100 accepts ER16 series collets. These collets are readily available in multiple sizes supporting tube diameters from 0.5 mm to 10 mm. The collet is retained with a threaded retaining cap that enables quick changeover to different tube diameters. The collet chuck is configured in a "fail-safe" mode where full clamping force is applied when no air pressure is present. Applying air pressure up to 100 psi adjusts the collet from fully closed to fully open. Air is delivered to the rotating collet assembly through a custom-designed frictionless, seal-less, rotary union. This 100% noncontact rotary union design ensures a lifetime of maintenance-free operation. The combination collet chuck and rotary union also has significantly less friction and inertia than external assemblies created from discrete parts. This reduced inertia improves system performance by allowing higher peak acceleration and reducing position error during laser machining operations.

Brushless Direct-Drive

The ASR1100 series utilizes direct-drive brushless motor technology to maximize positioning performance. Direct-drive technology is optimized for 24/7 production environments because there are no brushes to replace and no gear trains or belts to maintain. Direct drive also provides quicker acceleration and higher top speeds than gear- or belt-driven mechanisms, yielding higher total overall throughput. This makes the ASR1100 an excellent choice for processing small-diameter tubular materials.

The low maintenance and high throughput characteristics of the ASR1100 provide a stage that yields the lowest total cost of ownership.

Compact Packaging

The design of the ASR1100 series direct-drive rotary stage was optimized to minimize stage weight and rotating inertia. The resulting product, with a net overall weight under 5 kg, is significantly lighter than competitive product offerings. When used in a multi-axis system the lower weight results in an increase in performance for all positioning stages carrying the rotary stage.

Ordering Information

ASR1100 Mechanical-Bearing Direct-Drive Rotary Collect Stage

| Option | Description |

Speed (Required)

| Option | Description |

| -SS | Standard speed |

| -HS | High speed |

Connector (Required)

| Option | Description |

| -CN1 | 4-pin HPD motor and 25-pin D feedback connectors |

| -CN2 | 25-pin D motor and 25-pin D feedback connectors |

Rear Seal (Optional)

| Option | Description |

| -SL | Rear seal |

Mounting Plate (Optional)

| Option | Description |

| -MP | Mounting plate |

Wrench (Optional)

| Option | Description |

| -WR | Wrench for changing collet |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as a separate line item)

| Option | Description |

| Collet-ER16-CLTxx | ER16 DIN6499AA electropolished collet, 0.5 mm to 10 mm part diameter sizes available |

| CGF | Collet and gripper filtration kit |