Webinar

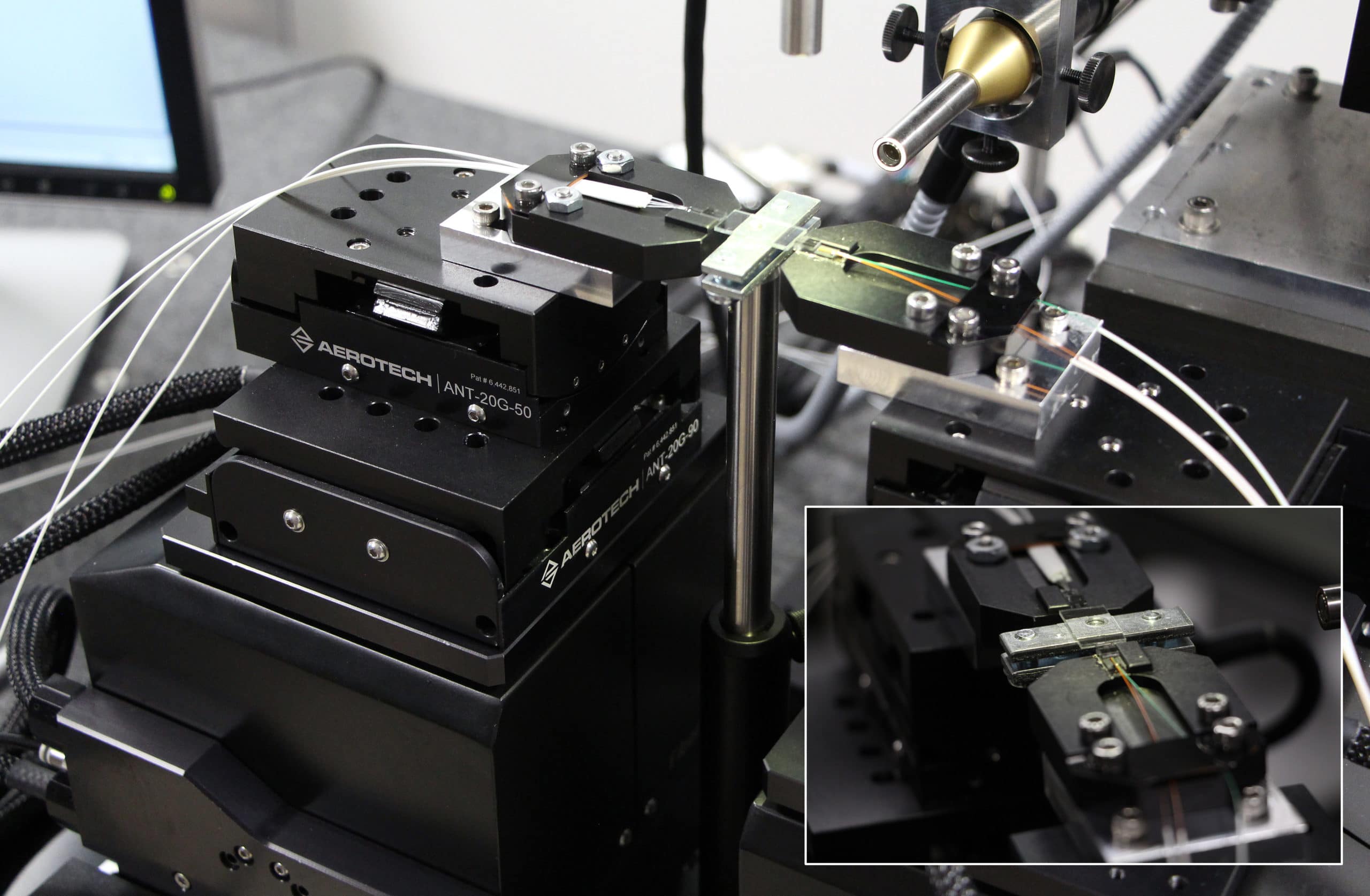

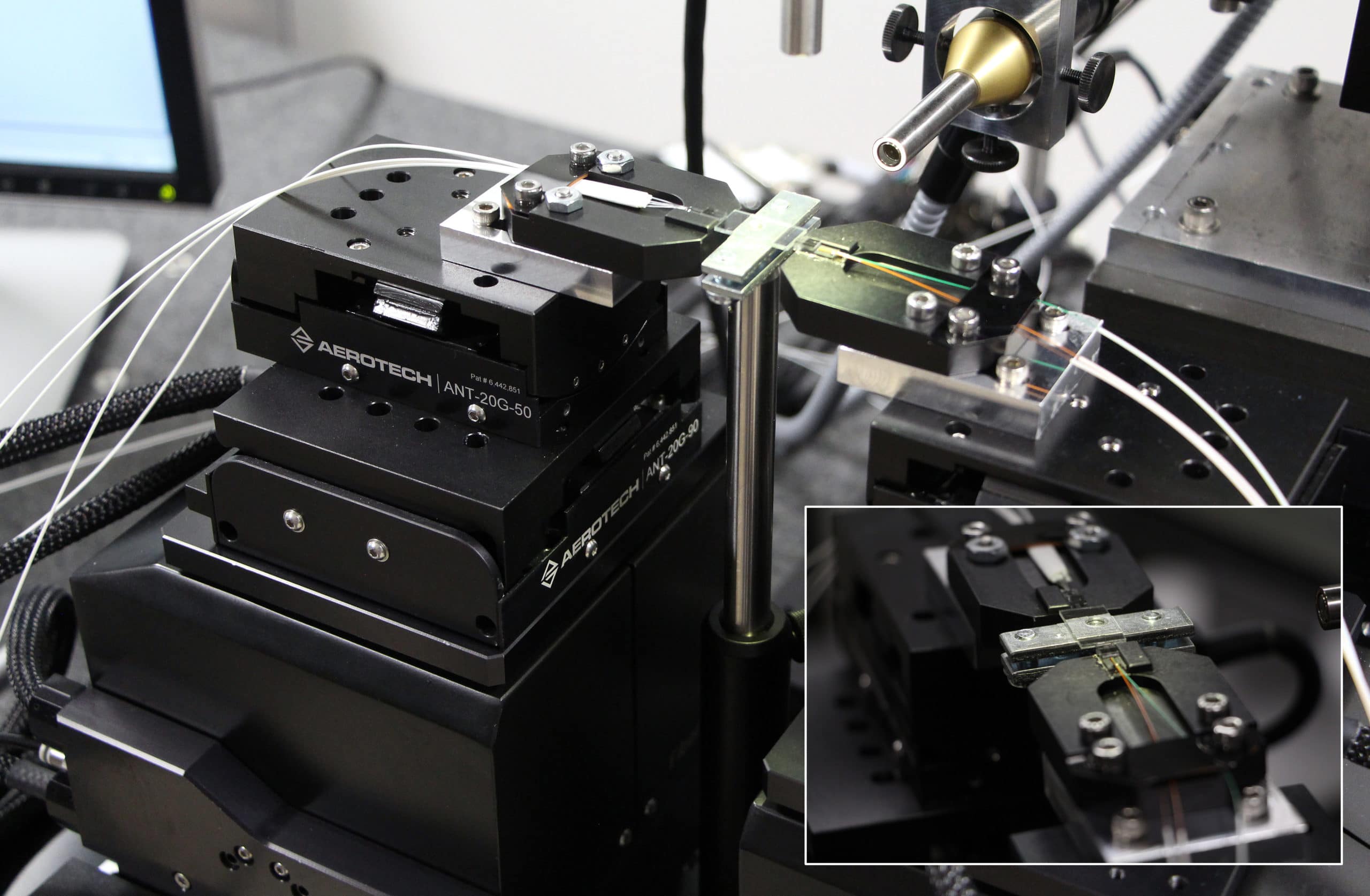

Positioning Equipment for Automated Fiber-Optics Device Manufacturing: Practical Ways to Solve Challenging Problems

About the Webinar

As fiber-optics device manufacturing processes mature, the use of automated alignment, probing and packing equipment will become widespread. These automated technologies will greatly enhance the precision of optical assemblies, while reducing production costs as volumes increase. However, selecting and implementing the right positioning subsystem within your manufacturing process is critical to meeting your machine’s performance expectations.

Learning Objectives

Presenter RJ Hardt, who has nearly a decade of experience solving challenging precision motion control and automation challenges for the optics and photonics industry, will explain the steps he takes to optimize the performance of automated positioning systems in the most difficult fiber-optics manufacturing processes.

RJ will address:

- Which motion control technologies to apply to achieve sub-micron alignment tolerances,

- Using motion kinematics to account for component coordinate offsets pre-alignment and

- Using precision position equipment to optimize optical power when facing difficult boundary conditions

He will teach attendees how to practically implement solutions related to motion control mechanical design, algorithm development and complex kinematics.

These solutions will alleviate common fiber-optics manufacturing challenges, including:

- Achieving the position resolution required to meet the alignment tolerances of the device being assembled

- Attaining the precision motion repeatability and durability that is needed to sustain high-volume manufacturing environments

Who Should Attend

Engineers and researchers who work with positioning equipment to solve fiber-optics manufacturing processes and are interested in practical solutions to challenging automation problems will benefit from this webinar. Additionally, any person who needs to develop an automation process to uncover new results in a lab setting, or achieve scale in a high-volume production setting, will also gain in-depth motion control expertise from this webinar.

RJ Hardt is a mechanical engineer and business development manager for Aerotech Inc., where he focuses on the optics and photonics industry. He helps companies perfect manufacturing or test processes by incorporating precise, reliable motion control and automation technologies. He has worked at Aerotech for more than eight years and has served in various mechanical and applications engineering roles. He holds a bachelor's degree in mechanical engineering from West Virginia University. Additionally, he has both a master's degree in mechanical engineering and an MBA from the University of Pittsburgh. You can contact RJ at rhardt@aerotech.com or +1.412.967.6890.