ACS-LP Mechanisch gelagerter, direkt angetriebener Drehtisch

Unsere ACS LP Drehtische mit integrierten ER-Spannzangenfuttern bieten automatisierte Materialhandhabung für eine Vielzahl von Materialien und Anwendungen.

Description

Specifications

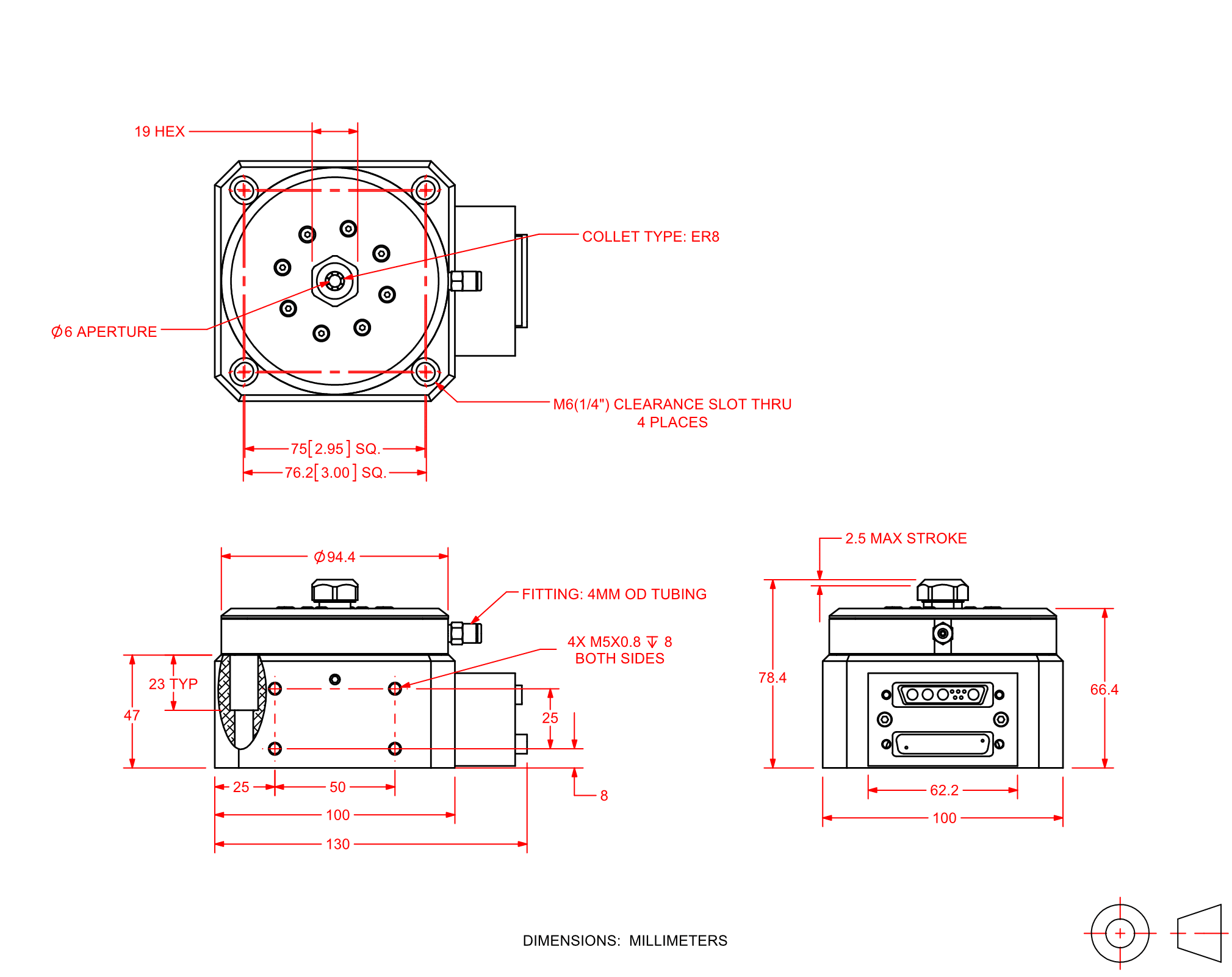

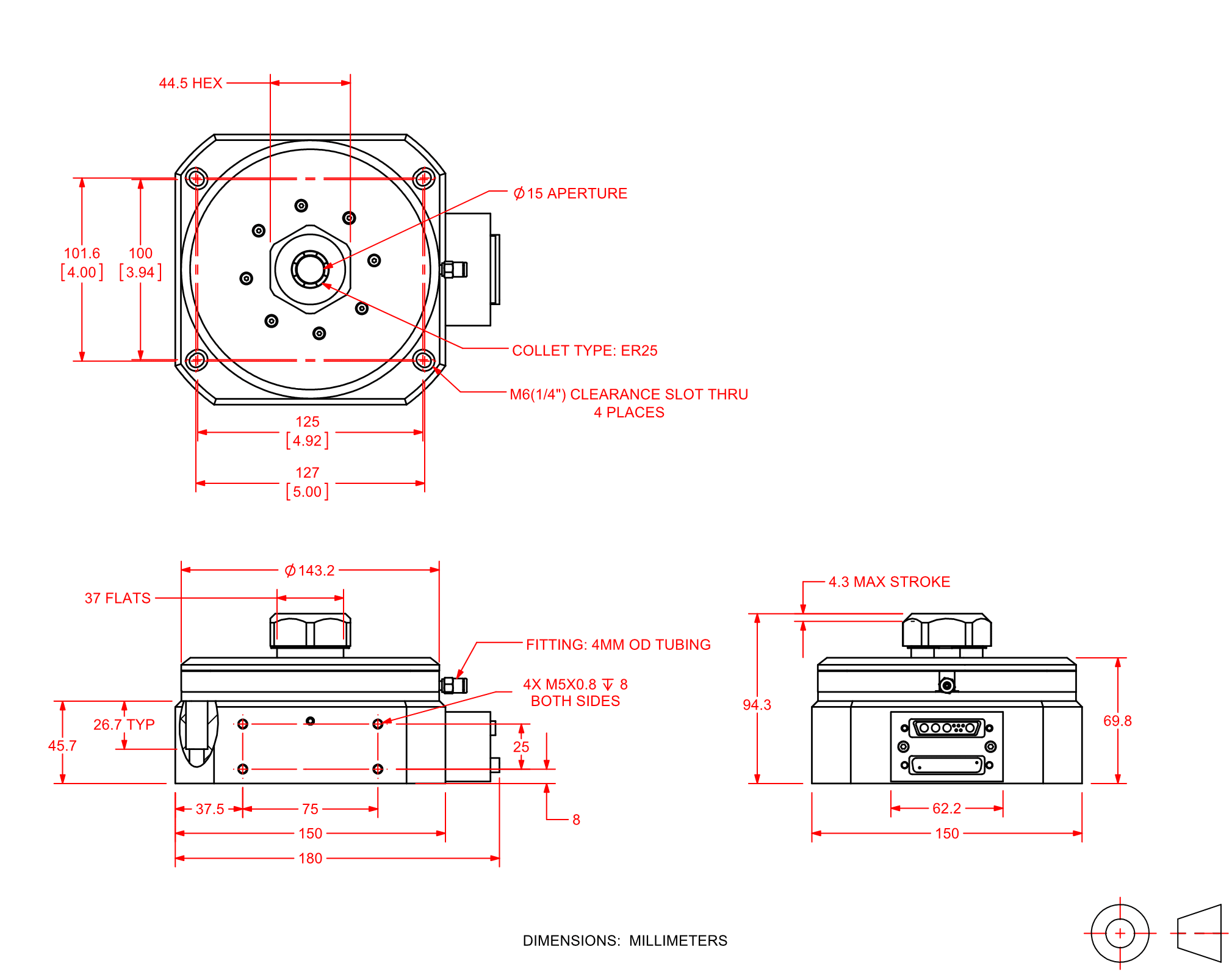

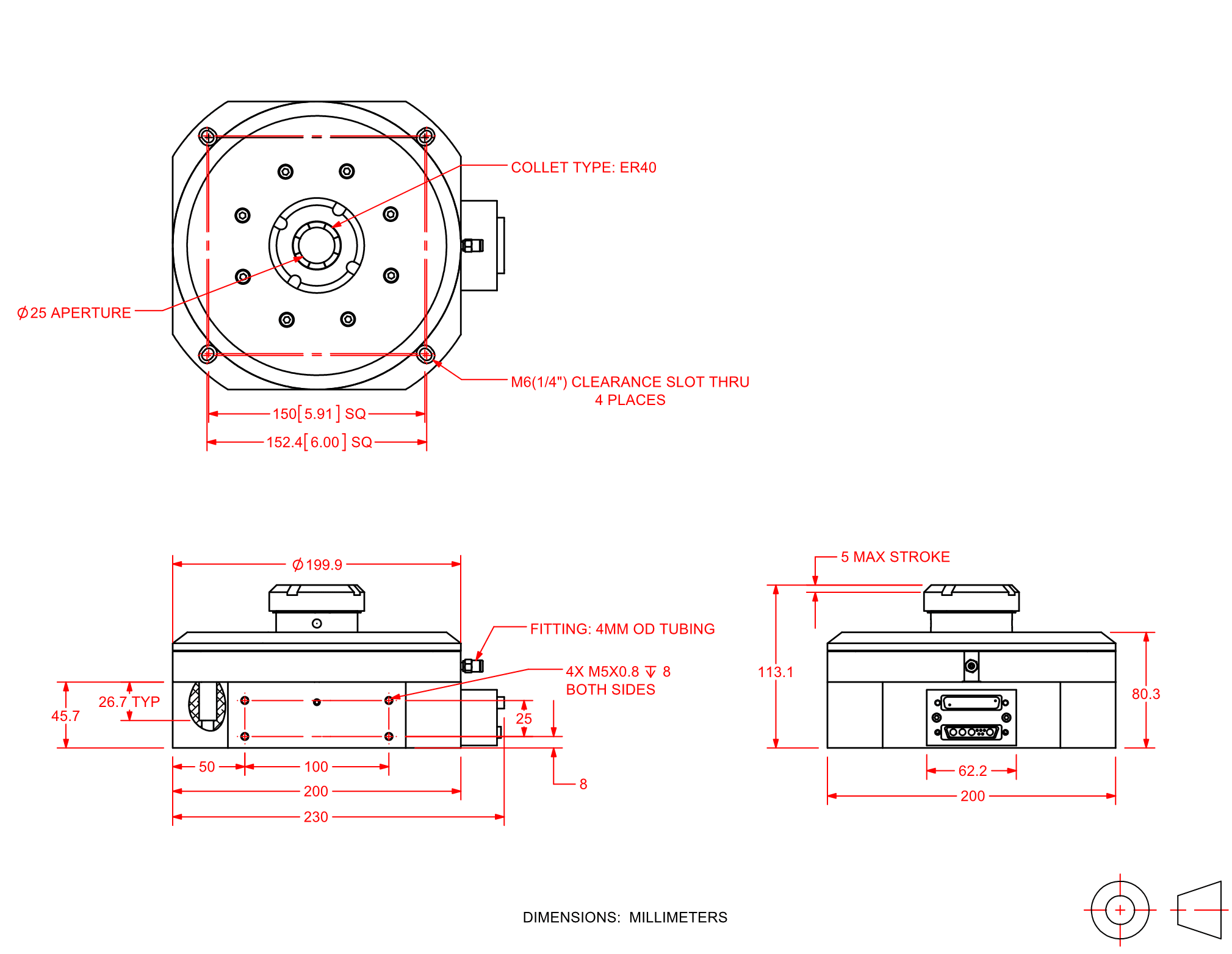

Dimensions

Ordering Info

Downloads

Description

Description

Specifications

Dimensions

Ordering Info

Downloads

Description

Gestaltungsmerkmale

- Integrale pneumatische ER-Spannzange

- Klare Öffnung für Produktdurchführung

- Trägheitsarme Welle für maximale Beschleunigung

- Integrale Drehdurchführung

- Ultraflaches Profil minimiert die Arbeitshöhe

Hochpräzise ER-Spannzange

Die Spannzange des ACS 100LP nimmt eine Spannzange der Serie ER8 auf, während der ACS 150LP eine ER25-Spannzange und der ACS 200LP eine ER40-Spannzange verwendet. Diese Spannzangen sind bei Lieferanten von Werkzeugmaschinenkomponenten in Größen erhältlich, die Rohrdurchmesser von 0,5 mm bis 30 mm unterstützen. ER-Spannzangen bieten hervorragende Rundlaufeigenschaften für Anwendungen, die ein hochpräzises Greifen von rohrförmigem Material erfordern. Die Spannzange wird mit einer Gewindehaltemutter gehalten, die einen schnellen Wechsel ermöglicht, und ist in einem ""ausfallsicheren"" normal-geschlossenen Modus konfiguriert, bei dem die volle Spannkraft angewendet wird, wenn kein Luftdruck vorhanden ist.

>Kompaktes Gehäuse

Das Design des direktangetriebenen Drehtisches der ACS LP-Serie wurde optimiert, um die Tischhöhe zu minimieren. Das niedrige Profil des Tisches reduziert die effektive Arbeitshöhe des Systems und minimiert dadurch ""Stack-up""-Fehler.

Integrale Drehdurchführung

Die Luft wird der Spannzange oder dem Greifer durch eine integrierte Drehdurchführung zugeführt, die eine dichtungslose, reibungsfreie Konstruktion verwendet. Diese 100 % berührungslose Drehdurchführung gewährleistet einen lebenslangen, wartungsfreien Betrieb. Die Kombination aus Spannzange und Drehdurchführung weist außerdem deutlich weniger Reibung und Trägheit auf als externe Baugruppen, die aus einzelnen Teilen bestehen. Diese geringere Trägheit verbessert die Systemleistung, indem sie höhere Spitzenbeschleunigungen ermöglicht und Positionsfehler bei der Laserbearbeitung reduziert.

>Bürstenloser Direktantrieb

Die ACS LP-Serie nutzt die bürstenlose Direktantriebstechnologie, um die Positionierleistung zu maximieren. Die Direktantriebstechnologie ist für Produktionsumgebungen mit 24/7-Betrieb optimiert, da keine Bürsten ausgetauscht werden müssen und keine Getriebe oder Riemen zu warten sind. Der Direktantrieb bietet außerdem eine schnellere Beschleunigung und höhere Höchstgeschwindigkeiten als zahnrad- oder riemengetriebene Mechanismen, was zu einem höheren Gesamtdurchsatz führt.

>Die wartungsarmen und durchsatzstarken Eigenschaften des ACS LP in Verbindung mit der integrierten Materialhandhabung sorgen für die niedrigsten Gesamtbetriebskosten im Vergleich zu Lösungen auf Komponentenebene.

Encoder Option |

ACS100LP |

ACS150LP |

ACS200LP |

| -E1 / -E2 / -E3 / -E4 | 1500 rpm | 600 rpm | 600 rpm |

| -E5 | 800 rpm | 300 rpm | 300 rpm |

Ordering Information

ACS100LP Mechanical-Bearing Direct-Drive Rotary Collet Stage

Chuck Style (Required)

| Option | Description |

| -ER8 | ER8 Ultra-Precision Collet |

| -ER8MB | ER8 Microbore Collet |

Feedback (Required)

| Option | Description |

| -E1 | Incremental Encoder, 1Vpp |

| -E2 | Incremental Encoder, TTL, x5 Interpolation |

| -E3 | Incremental Encoder, TTL, x10 Interpolation |

| -E4 | Incremental Encoder, TTL, x25 Interpolation |

| -E5 | Incremental Encoder, TTL, x50 Interpolation |

- Digital output encoder signals are synthesized with a 16 MHz clock. Care must be taken to ensure that the encoder sample rate on the controller is at least 16 MHz or higher. Slower clock rates are available on request.

Wrench (Optional)

| Option | Description |

| -WR | Wrench for Changing Collet |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, Uncalibrated with Performance Plots |

| -PL2 | Metrology, Calibrated (HALAR) with Performance Plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (To Be Ordered As Separate Line Item)

| Option | Description |

| Collet-ER8-CLTxx | ER8 DIN6499AA Electropolished Collet, 0.5 mm to 5 mm part diameter sizes available |

| Collet-ER8MB-CLTxx | ER8 DIN6499AA Electropolished Microbore Collet, 0.2 mm to 0.9 mm part diameter available |

| CGF | Collet and Gripper Filtration Kit |

ACS150LP Mechanical-Bearing Direct-Drive Rotary Collet Stage

Motor (Required)

| Option | Description |

| -M1 | Low Current, -A Winding |

Feedback (Required)

| Option | Description |

| -E1 | Incremental Encoder, 1 Vpp |

| -E2 | Incremental Encoder, TTL, x5 Interpolation |

| -E3 | Incremental Encoder, TTL, x10 Interpolation |

| -E4 | Incremental Encoder, TTL, x25 Interpolation |

| -E5 | Incremental Encoder, TTL, x50 Interpolation |

- Digital output encoder signals are synthesized with a 16 MHz clock. Care must be taken to ensure that the encoder sample rate on the controller is at least 16 MHz or higher. Slower clock rates are available on request.

Rear Seal (Optional)

| Option | Description |

| -SL | Rear Seal |

Wrench (Optional)

| Option | Description |

| -WR | Wrench for Changing Collet |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, Uncalibrated with Performance Plots |

| -PL2 | Metrology, Calibrated (HALAR) with Performance Plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (To Be Ordered As Separate Line Item)

| Option | Description |

| Collet-ER25-CLTxx | ER25 DIN6499AA Electropolished Collet, 0.5 mm to 15 mm part holding sizes available |

| CGF | Collet and Gripper Filtration Kit |

ACS200LP Mechanical-Bearing Direct-Drive Rotary Collet Stage

Motor (Required)

| Option | Description |

| -M1 | Low Current, -A Winding |

Feedback (Required)

| Option | Descrption |

| -E1 | Incremental Encoder, 1 Vpp |

| -E2 | Incremental Encoder, TTL, x5 Interpolation |

| -E3 | Incremental Encoder, TTL, x10 Interpolation |

| -E4 | Incremental Encoder, TTL, x25 Interpolation |

| -E5 | Incremental Encoder, TTL, x50 Interpolation |

- Digital output encoder signals are synthesized with a 16 MHz clock. Care must be taken to ensure that the encoder sample rate on the controller is at least 16 MHz or higher. Slower clock rates are available on request.

Rear Seal (Optional)

| Option | Description |

| -SL | Real Seal |

Wrench (Optional)

| Option | Description |

| -WR | Wrench for Changing Collet |

Metrology (Required)

| Option | Description |

| -PL1 | Metrology, Uncalibrated with Performance Plots |

| -PL2 | Metrology, Calibrated (HALAR) with Performance Plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (To Be Ordered As Separate Line Item)

| Option | Description |

| Collet-ER40-CLTxx | ER40 DIN6499AA Electropolished Collet, 15.5 mm to 25 mm part holding sizes available |

| CGF | Collet and Gripper Filtration Kit |

- ER40 collet sizes below 15.5 mm diameter are not supported. Use the ACS150LP if these sizes are required.